This basic machine consists of two loading areas, a processing cabinet with a de-leafing and cutting unit, one or two binders with a flexible collecting cloth and/or buffer belt behind this. Optionally, the machine can be modularly extended.

Processing lines (or bunching lines) have been developed for processing different types of flowers. Compared to the traditional way of bunching manually, the use of automatic processing lines increases productivity and reduces labour intensity. This results in a high-quality and uniform end product.

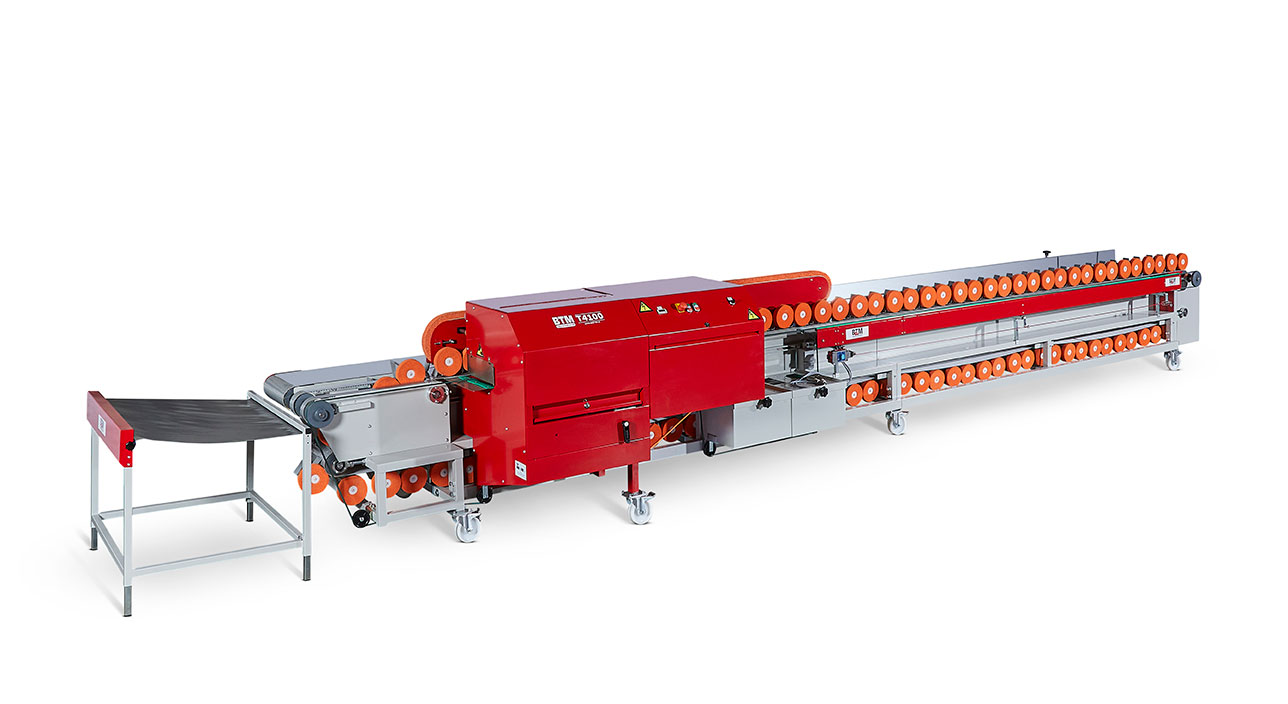

The T4100 Uniflor guarantees high production quality, optimal uniformity and considerable labour cost savings. In addition, the transport system is extremely product friendly and the T4100 can be used for practically all flower crops. Furthermore, because the Uniflor consists of various functional modules the machine can easily be adjusted.

The BTM T4127 is an advanced, robust flower processing line that, in addition to substantial labour cost savings, guarantees high quality and optimal uniformity of your product.

This machine is specially designed to effectively and reliably transport and process cut flowers in the greenhouse. The machine combines high production capacity with flexibility. In consultation with the customer, the T127 can be assembled in various versions.

![logo[1]](https://www.btm-bv.nl/wp-content/uploads/2019/12/logo1.png)